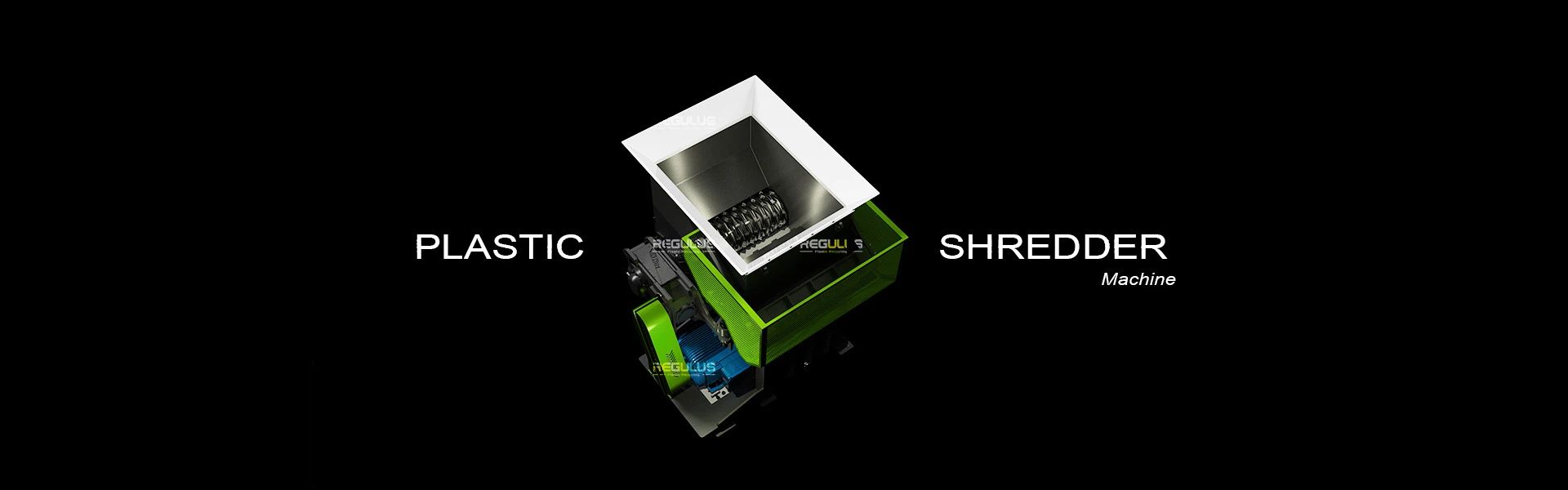

Plastic Shredder et Granulator II in I Machina

Product Details Design of Plastic Shredder et Granulator II in I Machina

Singula Singh Shredder et Granulator constructa simul.

Vastu plastic Shredder et crusher in unum apparatus habet duas partes in unum apparatus.

Prima pars shredding summo.

Secunda pars est adtritis partis, quae est in shredding partem ad bysso. Finem productum est 8-16mm particula materiae.

Post Shredding, Shredding materia vadit in Crusher apparatus directe.

Per hoc Shrdedding Crusing II-in-I Machina, Customer non opus ad buy balteum TRADUCTOR inter Shredder et Granulator, ita potest salvum sumptus et salvum spatium.

Applicationem de plastic Shredder et Granulator II in I Machina

In plastic shredder et Granulator II in I Machina est efficiens redivivus apparatus ad redivivus diversis generis vastum plastics.

Exempli gratia, plastic massas ex iniectio et extrusionem machina, plastic fistulae, plastic utres, plastic canistra, dolio, magna obstructionum, plastic, texta, lobortis (eg TV, etc).

Instructa diversis lamminis et driving ratio, in vastum plastic shredder et crusher in unum apparatus potest etiam propter lignum, cardboard, aeris funem etc.

Features de plastic Shredder et Granulator II in I Machina

Deserere plastic Shredder et Crusher in unum apparatus est sequenti characteribus:

| 1 | TempusShredding et adtritis munus in unum apparatus. Dimitti particula materiae mole potest reddi recta |

| 2 | Servo spatium nisi pretium. Shredder, crusher et repono ratio sunt coniuncta in unum apparatus. |

| 2 | Pelagus hastile agitur per calces reducer, magnus torque, stabilis operantes et humilis strepitu |

| 3 | Hydraulicarius pascentium mechanism, independens potentia unitas, fortis frame structuram |

| 4 | D2 laminis ad efficient opus et diu usura vitae Material fortitudinem et minui acriter post shredding, minus crusher accentus, quod potest amplio cultro muneris vitae. |

| 5 | Hydrau ratio aqua refrigerationem consilio |

| 6 | Electrical scrinium cum Siemens PLC control ratio. Auto Control ad Co-Rotation et Reversal Auto tutela dum super-onus Et machina animadverto firmum et tutum opus per automaic imperium de Shredder, Crusher et repono efficientiam |

| 7 | Totam occurrat CE salus vexillum. |

Main Technical parametri

| Exemplar | SP2260 | SP4060 | SP4080 | SP40100 |

| A (mm) | MDCCCLXX | MMCDLXX | MMDCCLXX | MMDCCLXX |

| B (mm) | MCDXX | MDCCXX | MCMLXX | MMCLXX |

| C (mm) | DCL | MCL | MCCC | MCCC |

| D (mm) | DC | DC | DCCC | M |

| E (mm) | DCC | DCCCLV | DCCCLV | DCCCLV |

| H (mm) | MDCCC | MMCC | MMCC | MMCC |

| Shredding Part: | ||||

| Cylindrus ictum (mm) | DC | DCC | DCCCL | DCCCL |

| Rotor diameter (mm) | Φ270 | φ400 | φ400 | φ400 |

| Shredder Shaft Volo (RPM) | 83 | 83 | 83 | 83 |

| Rotor laminis (PCs) | 26 | 34 | 46 | 58 |

| Fixum (PCs) | 1 | 2 | 2 | 2 |

| Main Motor Power (KW) | 22 | 30 | 37 | 45 |

| Motor Power Hydraulica (KW) | 2.2 | 2.2 | 2.2 | 2.2 |

| Partes: | ||||

| Crusher motor potentia (KW) | 15 | 22 | 30 | 37 |

| Crusher Gyratorius (PCs) | 18 | 18 | 24 | 30 |

| Crusher fixa (PCs) | 2 | 2 | 4 | 4 |

| Crusher screen mesh (mm) | 12 | 12 | 12 | 12 |

| CERAULA motricium Power (KW) | 2.2 | 3 | 4 | 5.5 |

| Machina pondus (kg) | MMDCCC | MMMDC | (IV) DC | (V) D |

Detailed photos